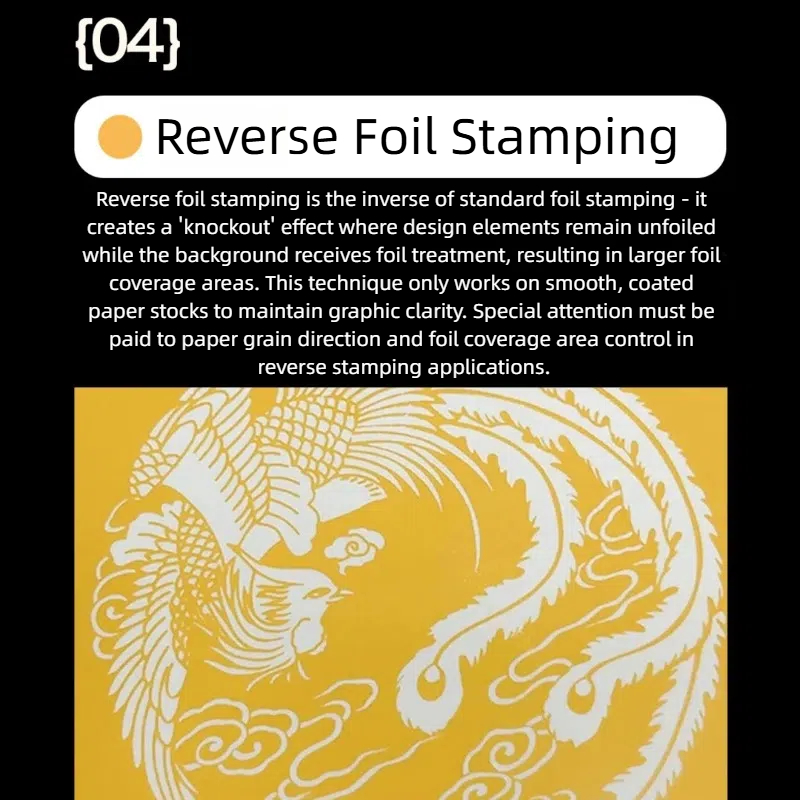

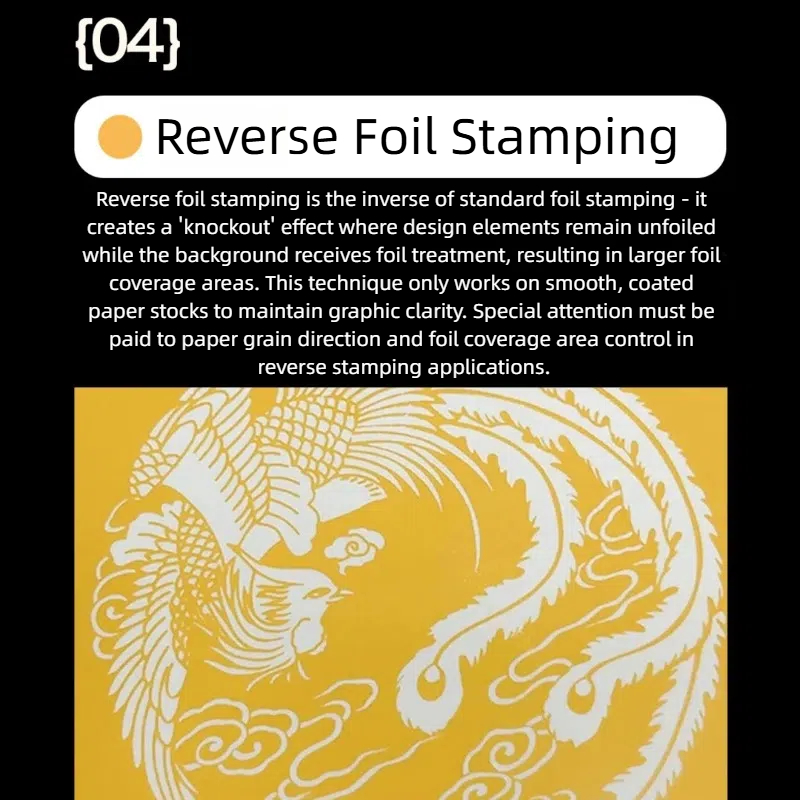

Reverse Foil Stamping

Reverse foil stamping is the inverse of standard foil stamping - it creates a 'knockout' effect where design elements remain unfoiled while the background receives foil treatment, resulting in larger foil coverage areas. This technique only works on smooth, coated paper stocks to maintain graphic clarity. Special attention must be paid to paper grain direction and foil coverage area control in reverse stamping applications.

Reverse foil stamping (also called negative foil stamping) is an advanced technique where foil is applied to the background of a design, leaving the main elements unfoiled (knocked out). This creates high-contrast metallic effects with sharp, clean edges.

Key Features

✔ High Visual Impact – Bold metallic backgrounds with uncoated negative space

✔ Design Flexibility – Works with intricate logos, typography, and patterns

✔ Anti-Counterfeiting – Difficult to replicate precisely due to registration demands

✔ Premium Perception – Used in luxury packaging for a sophisticated look

Common Applications

Luxury Branding

Champagne/wine labels (e.g., foil-background with matte-text logos)

High-end cosmetic packaging (e.g., black foil with negative-space brand names)

Security Features

Micro-text foil backgrounds on pharmaceutical boxes

Holographic reverse foil for authentication

Minimalist Designs

"Hidden" metallic effects (e.g., foil reveals light angles)

Contrast textures (matte unfoiled elements vs. glossy foil)

Sustainable Packaging

Partial foil coverage reduces material usage vs. full foil stamping

Process Workflow

Design Preparation

Artwork must have clear positive/negative separation

Foil area typically covers 60–90% of the design

Die Creation

Precision-etched brass dies (tolerances ≤0.05mm)

Silicone counterforce plates for even pressure

Stamping Execution

Temperature: 110–140°C (depends on substrate)

Pressure: 25–40 kg/cm²

Speed: Slower than flat foil for perfect registration

Substrate Compatibility

Best for smooth, coated stocks (e.g., art paper, laminated boards)

Avoid porous/uncoated materials (foil adhesion issues)

Technical Comparison: Reverse vs. Standard Foil

| Factor | Reverse Foil Stamping | Standard Foil Stamping |

|---|---|---|

| Foil Coverage | Background only | Design elements only |

| Registration | Critical (±0.1mm tolerance) | Less stringent (±0.3mm) |

| Cost | 20–30% higher (precision dies) | Lower |

| Effect | Negative-space metallic glow | Direct metallic elements |