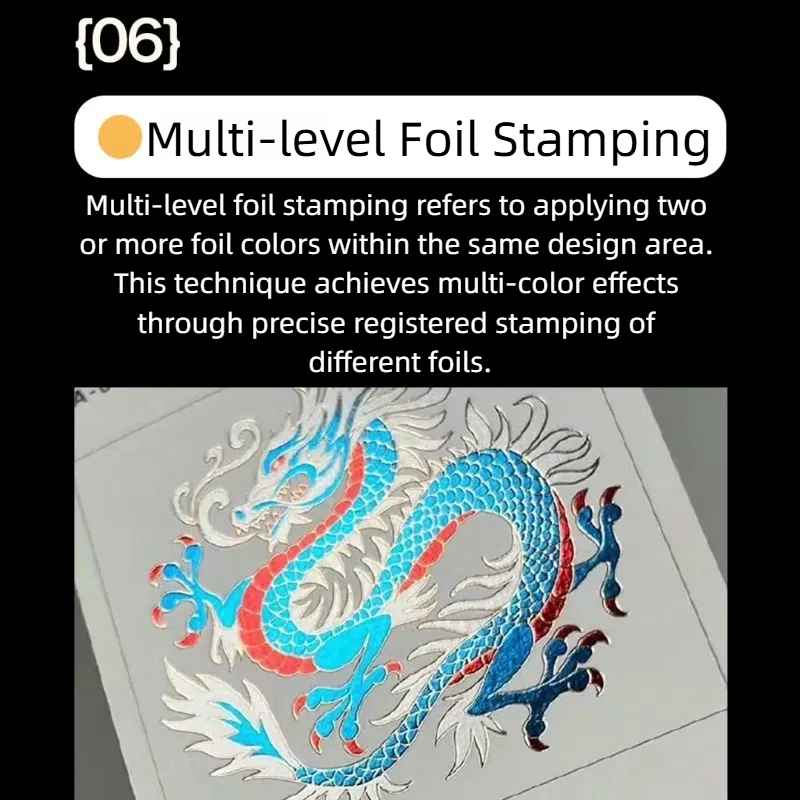

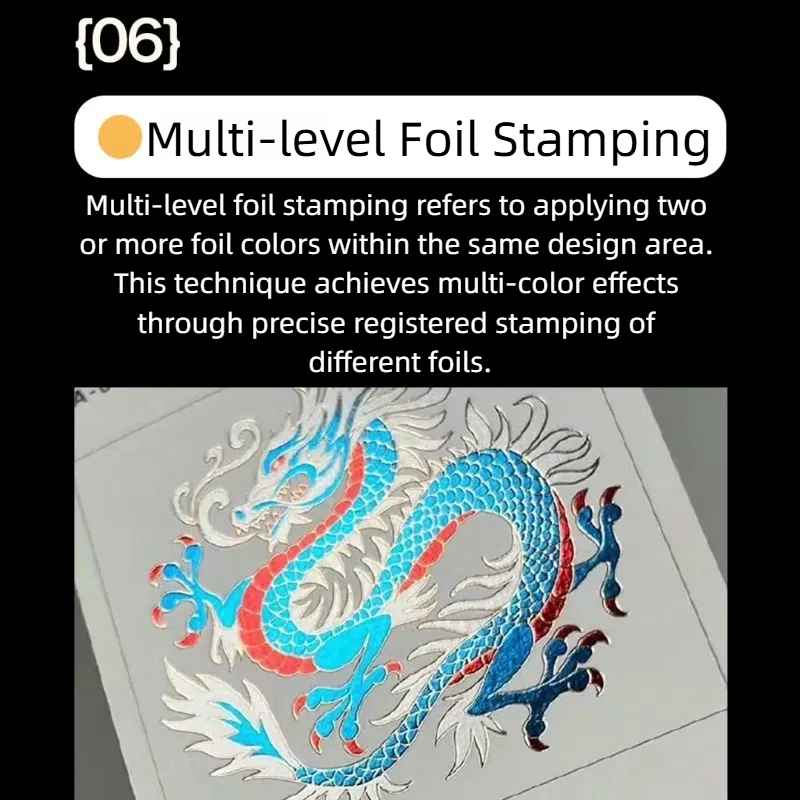

Multi-Level Foil Stamping

Multi-level foil stamping refers to applying two or more foil colors within the same design area. This technique achieves multi-color effects through precise registered stamping of different foils.

Multi-level foil stamping is an advanced decorative technique that combines two or more foil colors/textures with variable embossing depths in a single pass. It creates intricate, dimensional designs with layered metallic effects, often used for ultra-premium packaging.

Key Features

✔ True 3D Effects – Simultaneous foil transfer + multi-depth embossing

✔ Color Layering – Precise registration of multiple foils (e.g., gold + holographic)

✔ Tactile Complexity – Combines raised/recessed areas with foil contrasts

✔ Anti-Counterfeiting – Nearly impossible to replicate with digital methods

Technical Process

Die Manufacturing

Tiered Brass Dies: Each level corresponds to a foil color/depth

Registration Tolerance: ≤0.05mm between layers

Foil Feeding System

Sequential or synchronized application of:

Metallic foils (gold/silver)

Pigmented foils (matte colors)

Special effects (holographic, transparent)

Stamping Parameters

Temperature: 130–160°C (varies by foil type)

Pressure: 40–60 kg/cm² (adjusted per depth level)

Dwell Time: 1.5–3 seconds (longer than standard foil)

Substrate Requirements

Thick stocks (≥400gsm board, leather, acrylic)

Avoid stretchable materials (e.g., thin plastics)

Applications in Luxury Packaging

| Industry | Use Case | Example |

|---|---|---|

| Spirits | Limited-edition bottle labels | Rémy Martin Louis XIII cognac cases |

| Watches | Presentation box liners | Patek Philippe wood+foil gift packaging |

| Cosmetics | High-end compact lids | Dior Prestige collection embossed compacts |

| Automotive | Luxury car brand gift sets | Bentley leather+foil accessory boxes |

Comparison: Multi-Level vs. Standard Foil

| Factor | Multi-Level Foil Stamping | Standard Foil Stamping |

|---|---|---|

| Color Capacity | 2–4 foil layers in one pass | Single foil only |

| Embossing Depth | Variable (0.2–1.5mm) | Flat or uniform depth |

| Cost | 3–5× higher (complex tooling) | Lower |

| Production Speed | 50–70% slower | Faster |

| Effect | Museum-quality tactile+visual art | Basic metallic enhancement |