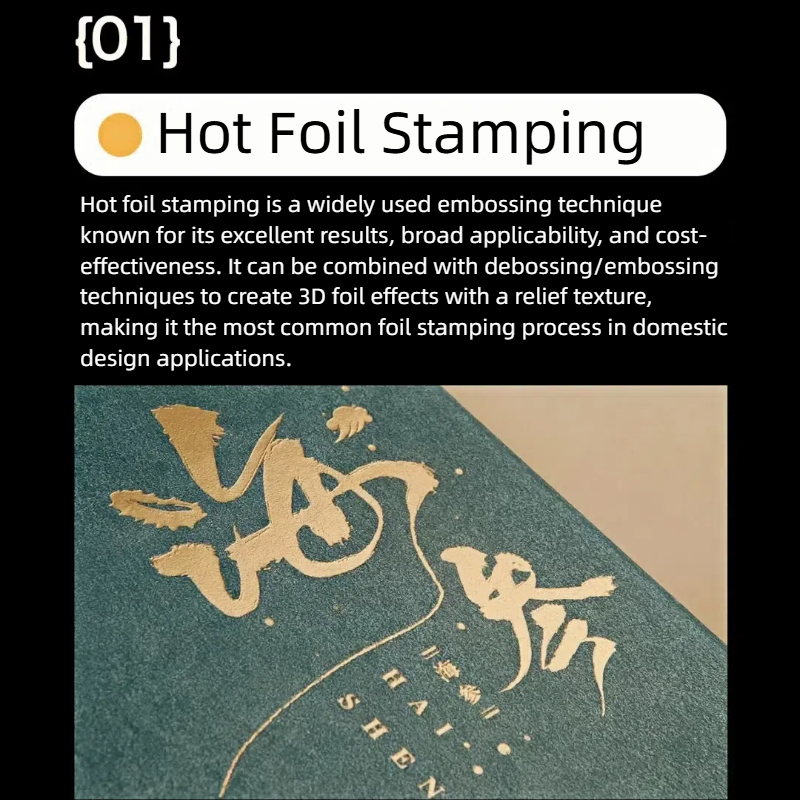

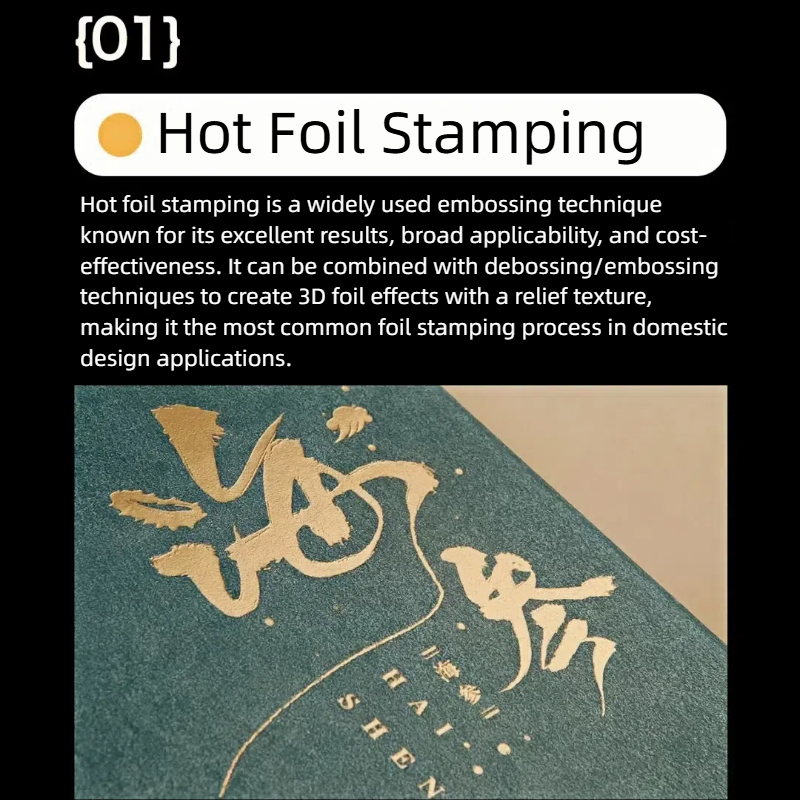

Hot Foil Stamping

Hot foil stamping is a widely used embossing technique known for its excellent results, broad applicability, and costeffectiveness. It can be combined with debossing/embossing techniques to create 3D foil effects with a relief texture, making it the most common foil stamping process in domestic design applications.

Hot foil stamping is a premium finishing process that transfers metallic, pigmented, or holographic foil onto packaging substrates using heated dies under pressure. It enhances visual appeal, brand perception, and anti-counterfeiting features.

Key Applications in Packaging

Luxury Packaging

Cosmetic boxes, perfume cartons, jewelry cases

Example: Gold foil-stamped logos on premium skincare packaging

Brand Identity Elements

Logos, monograms, typography

Example: Embossed foil brand names on liquor bottles

Security Features

Holographic foils for anti-counterfeiting

Example: Pharmaceutical packaging with tamper-evident foil stamps

Tactile Enhancement

Combined with embossing for 3D effects

Example: Textured foil patterns on high-end chocolate boxes

Technical Process Workflow

Die Preparation

Material: Brass (precision) or magnesium (cost-effective)

Engraving: CNC or chemical etching

Foil Selection

Metallic (gold/silver), matte/gloss pigments, diffractive foils

Stamping Parameters

Temperature: 100–150°C (substrate-dependent)

Pressure: 20–35 kg/cm²

Dwell Time: 0.5–2 seconds

Substrate Compatibility

Paperboard, laminated stocks, synthetic papers, some plastics

Advantages vs. Cold Foil

| Factor | Hot Foil Stamping | Cold Foil Stamping |

|---|---|---|

| Visual Effect | High gloss, deep metallic sheen | Matte/semi-gloss metallic finish |

| Durability | Abrasion-resistant | Prone to scratching |

| Cost Efficiency | Better for small runs | Economical for mass production |

| Design Flexibility | Compatible with embossing | Limited to flat applications |