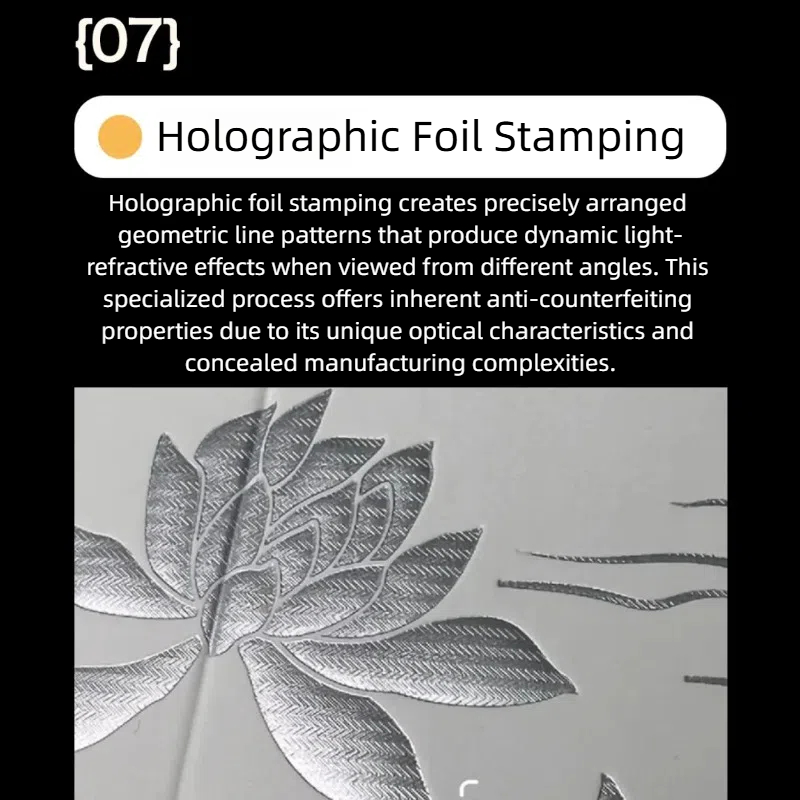

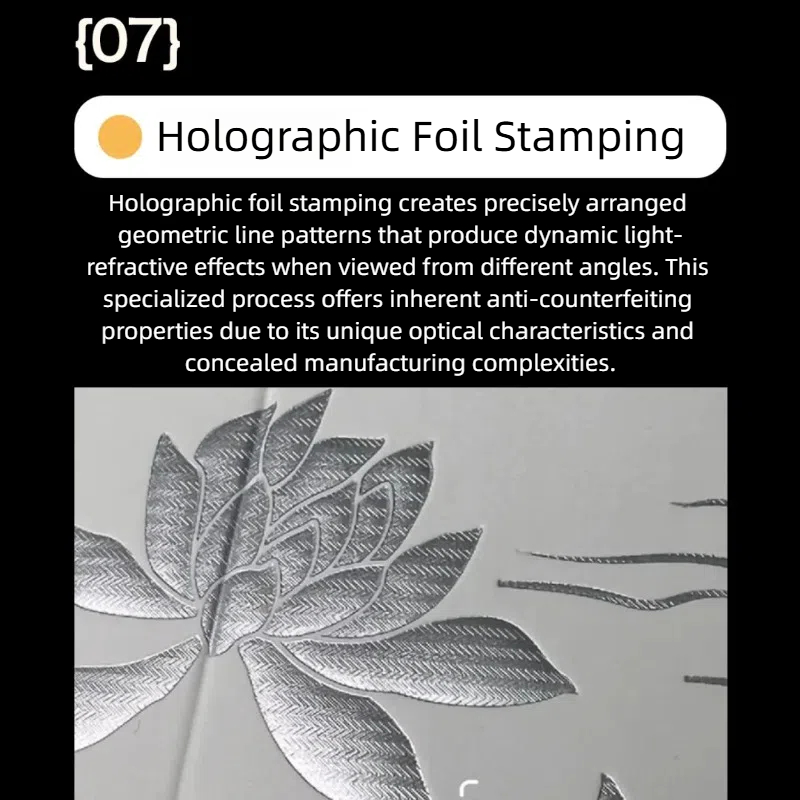

Holographic Foil Stamping

Holographic foil stamping creates precisely arranged geometric line patterns that produce dynamic light-refractive effects when viewed from different angles. This specialized process offers inherent anti-counterfeiting properties due to its unique optical characteristics and concealed manufacturing complexities.

Holographic foil stamping is a high-security decorative process that applies light-diffracting foil patterns to packaging substrates using heat and pressure. It produces dynamic, color-shifting optical effects that vary with viewing angles, serving both aesthetic and anti-counterfeiting purposes.

Key Features

✔ Optical Security – Micro-engraved holograms deter duplication

✔ Visual Impact – Rainbow color shifts (e.g., gold-to-green transitions)

✔ Brand Protection – Custom holographic patterns for authentication

✔ Versatility – Works with hot stamping, cold foil, or digital methods

Technical Process

Holographic Foil Types

2D/3D Holograms: Geometric patterns with depth illusion

Dot-Matrix: Micro-perforated security codes (≤0.1mm dots)

Kinetic Effects: Animated visuals when tilted

Tooling Requirements

Brass/Magnesium Dies: Precision-etched to match hologram relief

Silicon Counterforce: Even pressure distribution

Stamping Parameters

Temperature: 110–140°C (varies by foil brand)

Pressure: 25–40 kg/cm²

Speed: 1,000–3,000 impressions/hour

Substrate Compatibility

Best for: Coated paper, synthetic films, laminated boards

Avoid: Rough/uncoated surfaces (causes foil fragmentation)

Applications in Packaging

| Industry | Use Case | Example |

|---|---|---|

| Pharmaceutical | Tamper-evident seals | Pfizer vaccine packaging holograms |

| Liquor | Premium bottle neck bands | Johnnie Walker Blue Label security strips |

| Electronics | Authenticity labels | Apple AirPods case holographic stickers |

| Cosmetics | Luxury compact mirrors | Chanel No.5 limited-edition holographic lids |

Comparison: Holographic vs. Standard Metallic Foil

| Factor | Holographic Foil | Standard Metallic Foil |

|---|---|---|

| Light Interaction | Dynamic color shifts | Static reflection |

| Security Level | High (custom patterns possible) | Low (easily replicated) |

| Cost | 2–3× more expensive | Lower |

| Tooling | Requires hologram-specific dies | Generic dies acceptable |