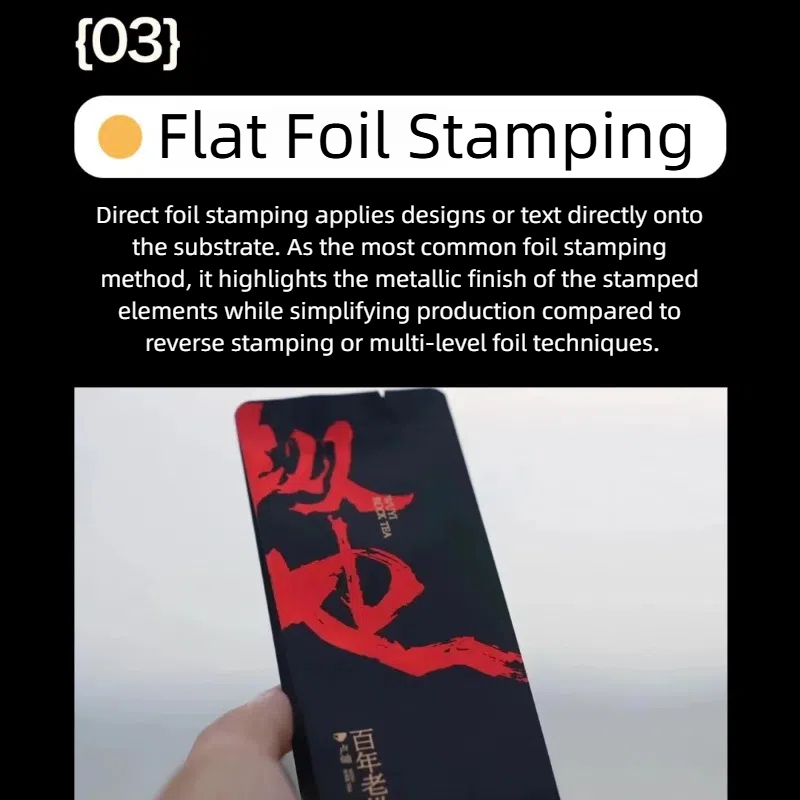

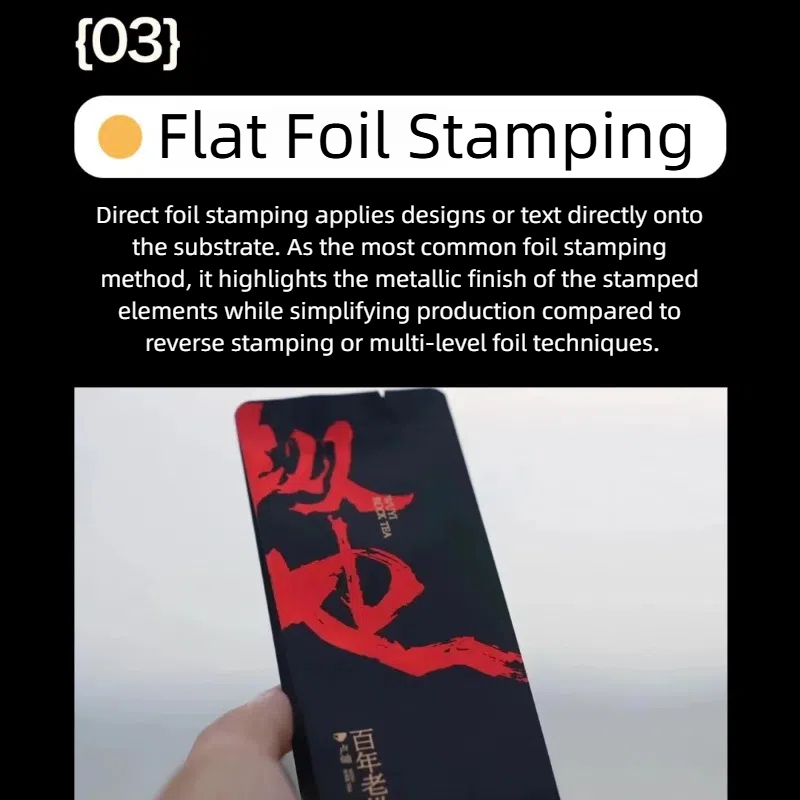

Flat Foil Stamping

Flat foil stamping is direct foil stamping applies designs or text directly onto the substrate. As the most common foil stamping method, it highlights the metallic finish of the stamped elements while simplifying production compared to reverse stamping or multi-level foil techniques.

Flat foil stamping (also called standard foil stamping) is a traditional hot stamping process that applies metallic or pigmented foil onto packaging surfaces without creating dimensional effects (unlike embossed/debossed foil). It delivers a smooth, high-gloss, or matte finish for premium branding.

Key Features

✔ Smooth Surface – No tactile embossing; pure metallic/pigmented finish

✔ Cost-Effective – Lower tooling costs vs. 3D foil stamping

✔ High Precision – Sharp edges for fine details (text, logos, borders)

✔ Material Flexibility – Works on paper, cardboard, laminates, and some plastics

Common Applications in Packaging

Brand Logos & Typography

Gold/silver foil branding on cosmetic boxes

Matte black foil for minimalist luxury packaging

Security & Anti-Counterfeiting

Holographic foil stamps on pharmaceutical boxes

Scratch-off verification labels

Decorative Elements

Geometric patterns on gift boxes

Gradient foil effects (e.g., Pantone metallics)

Sustainable Packaging

Recyclable foil options on eco-friendly cartons

Process Comparison: Flat vs. 3D Foil Stamping

| Factor | Flat Foil Stamping | 3D Foil Stamping |

|---|---|---|

| Surface Texture | Smooth | Raised/indented (embossed) |

| Tooling Cost | Lower (single-level dies) | Higher (multi-level dies) |

| Production Speed | Faster (single-step process) | Slower (requires precise pressure) |

| Visual Impact | Elegant, subtle metallic shine | Bold, tactile luxury effect |

Technical Considerations

Substrate Requirements

Works best on coated papers (gloss/matte) for optimal adhesion

Avoid textured surfaces (may cause uneven foil transfer)

Foil Types

Metallic (gold, silver, rose gold)

Pigmented (matte black, white, pastels)

Special Effects (holographic, diffractive, transparent)

Printing Integration

Can be combined with offset/digital printing for hybrid designs

Requires precise registration (±0.1mm tolerance)