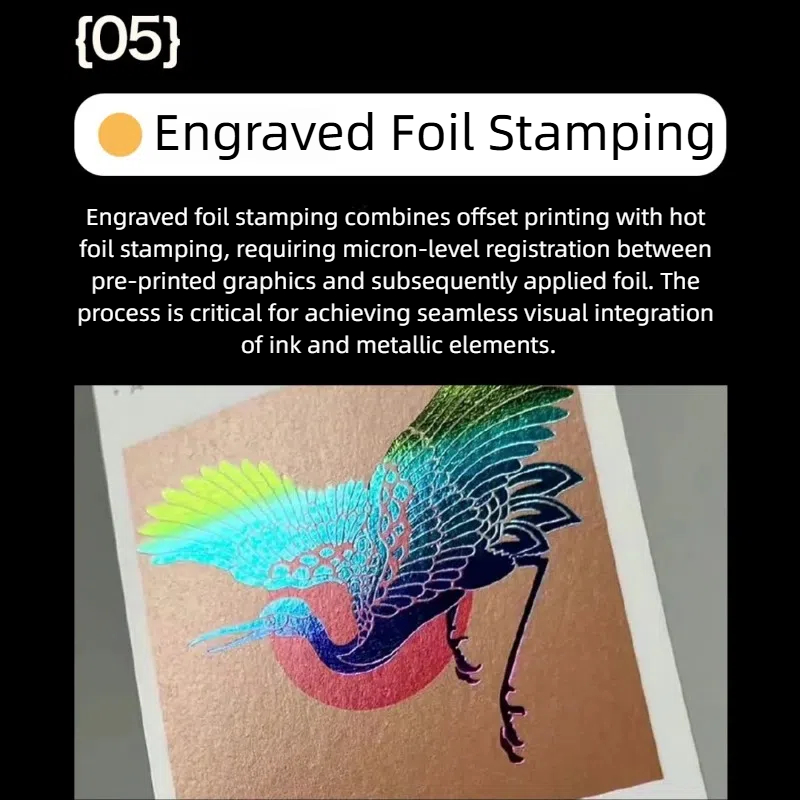

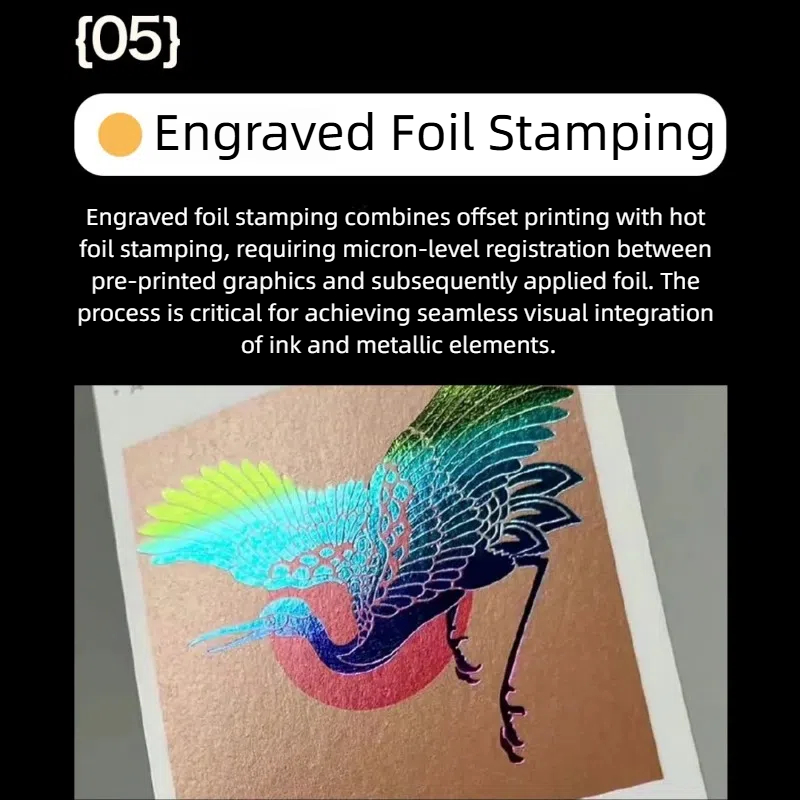

Engraved Foil Stamping

Engraved-style foil stamping is an innovative integration of foil stamping and printing. The process involves first printing the design, then precisely aligning and stamping metallic foil over the printed graphics. This technique demands extremely high registration accuracy throughout production.

Engraved-style foil stamping is a premium decorative technique that replicates the look of traditional metal engraving through precisely etched dies and specialty foils. It creates intricate, recessed metallic designs with dimensional depth, often combined with embossing for tactile enhancement.

Key Features

✔ Luxury Aesthetic – Mimics hand-engraved metalwork (common in high-end spirits/watches)

✔ Tactile Precision – Slightly recessed foil with crisp edges

✔ Anti-Counterfeiting – Complex patterns resist duplication

✔ Material Efficiency – Uses thinner foil stocks than standard hot stamping

Process Breakdown

Die Creation

CNC-Engraved Brass Dies: 0.02–0.1mm line precision

Depth Control: 0.3–0.8mm recessed areas

Foil Selection

Pigmented Foils: Matte gold/silver for antique effects

Transparent Foils: Overprinted colors for layered effects

Stamping Parameters

Temperature: 120–150°C (lower than standard hot foil)

Pressure: 30–50 kg/cm² (higher for depth consistency)

Substrate Compatibility

Best for dense stocks (≥300gsm coated board, synthetic leather)

Avoid fluted/rough surfaces

Applications in Luxury Packaging

| Industry | Use Case | Example |

|---|---|---|

| Spirits | Bottle collars, gift boxes | Johnnie Walker King George V limited edition |

| Cosmetics | Compact cases, lipstick tubes | Guerlain Meteorites pressed powder compacts |

| Confectionery | Premium chocolate sleeves | Godiva gold-engraved truffle boxes |

| Jewelry | Velvet case liners, authenticity cards | Tiffany & Co. signature blue boxes |

Technical Comparison

| Factor | Engraved-Style Foil | Standard Hot Foil |

|---|---|---|

| Line Precision | 0.05mm min. line width | 0.15mm min. |

| Production Speed | 20–30% slower | Faster |

| Tooling Cost | 40–60% higher (complex dies) | Lower |

| Effect | Recessed metallic "carving" look | Surface-level metallic coating |