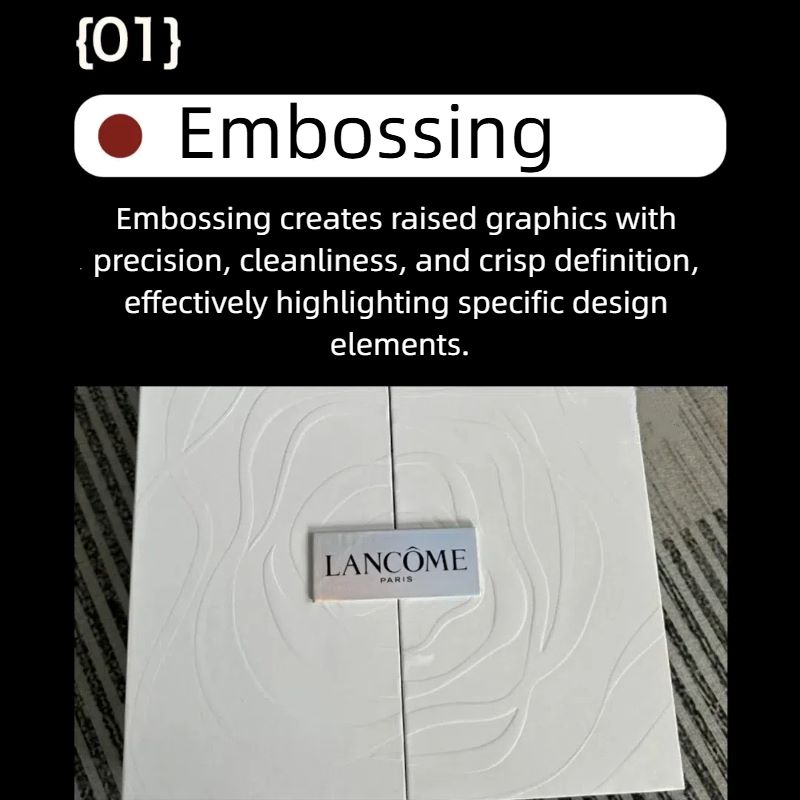

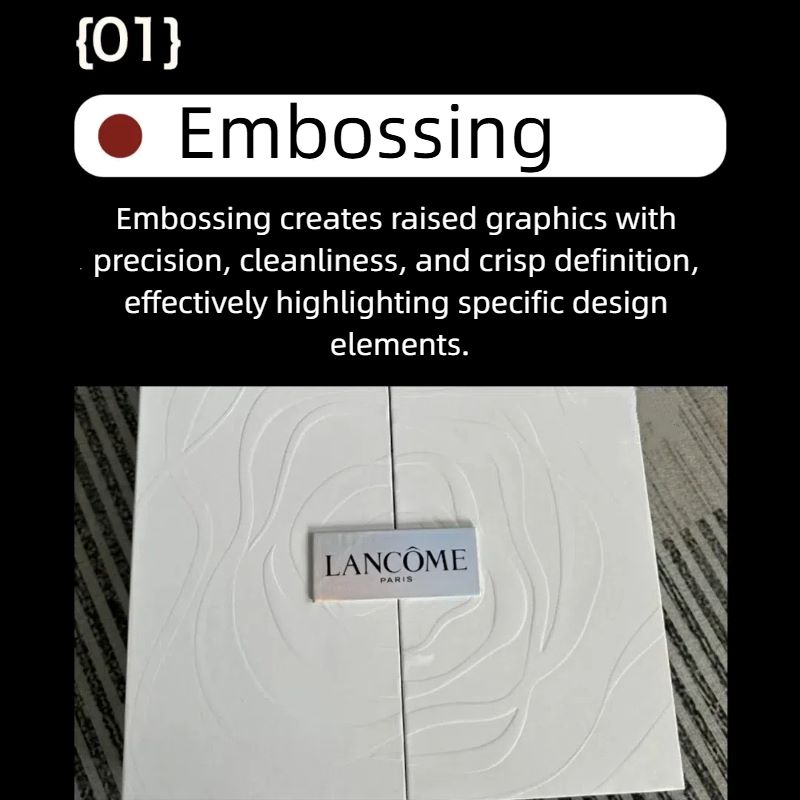

Embossing

Embossing is a specialty finishing technique that creates raised, three-dimensional designs on paper, cardboard, or other substrates. It adds tactile depth and visual prestige to printed materials.

How It Works:

Die Creation: A custom metal die (male) and counter-die (female) are precision-engraved with the design.

Substrate Preparation: Printed material is placed between the dies.

Pressure Application: Under high heat and pressure, the dies compress the substrate, permanently raising the design.

Result: A sculpted, tactile surface that catches light and shadows.

Key Applications

Premium Packaging: Luxury product boxes, wine labels, cosmetic sleeves.

Stationery: Business cards, letterheads, invitations.

Branding: Logos, monograms, security features on certificates.

Publications: Book covers, art portfolios.

Technical Considerations

| Factor | Details |

|---|---|

| Substrates | Works best on thicker stocks (≥220gsm): cardstock, kraft paper, leather, some synthetics. |

| Design Tips |

Use bold lines/solid shapes (fine details may not lift cleanly).

Avoid extreme gradients or fragile elements.

Combine with foil stamping for "foil embossing" effect.

Types |Single-Level: Uniform height (most common).

Multi-Level: Tiered elevations (e.g., mountains vs. foothills).

Scorching: Adds dark shadows via controlled burning.

Debossing: Recessed design (opposite of embossing).

Why Use Embossing?

Tactile Appeal: Engages touch and sight for memorable unboxing/experiences.

Perceived Value: Signals luxury and craftsmanship (e.g., Tiffany & Co. packaging).

Brand Differentiation: Stands out in competitive markets.

Subtle Sophistication: Elevates minimalist designs without color/ink.

Industry Terminology

Brass Dies: Most durable for long print runs.

Magnesium Dies: Cost-effective for short runs.

Register Embossing: Aligns embossed area with printed elements.

Blind Embossing: No ink/foil – pure texture only.