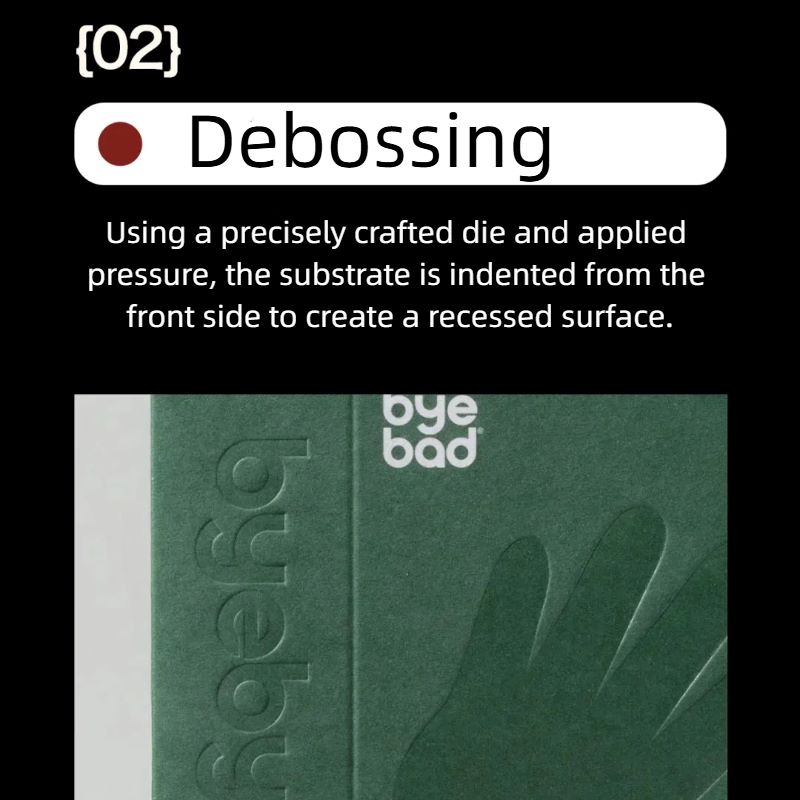

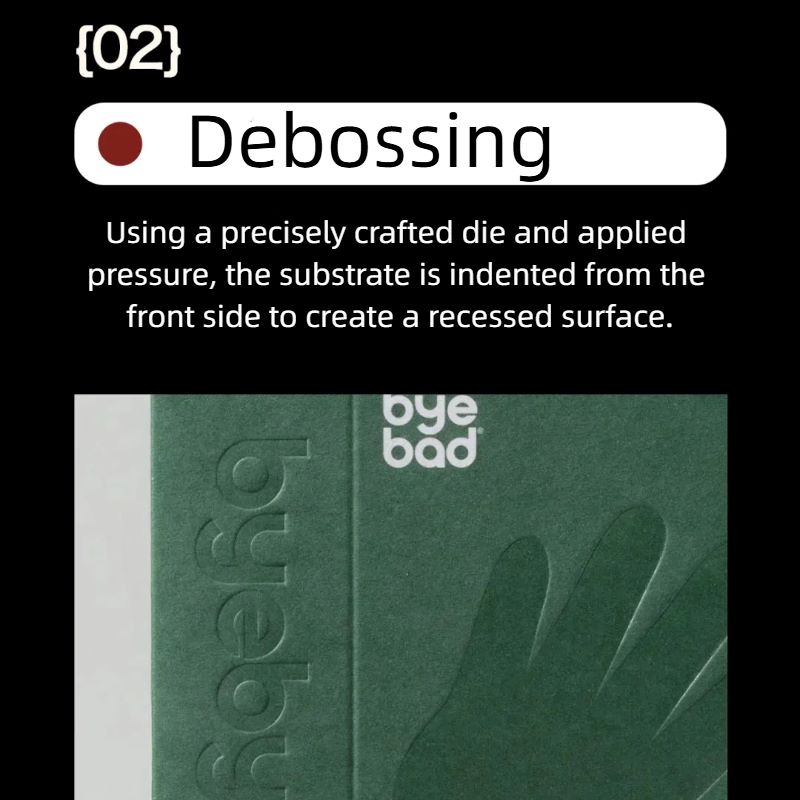

Debossing

Debossing is a specialty finishing technique that presses a design into a substrate, creating a recessed, indented effect. Unlike embossing (which raises surfaces), debossing adds subtle depth and sophistication through controlled depression.

Key Process Steps:

Die Preparation: A custom metal die (male) and counter-die (female) are precision-engraved.

Substrate Alignment: Material is secured between dies.

Pressure Application: High heat/pressure forces the die into the substrate, permanently indenting the design.

Result: A sunken, tactile graphic with shadow-play for understated elegance.

Applications & Use Cases

Luxury Packaging: Wine labels, cosmetic lids, premium gift boxes

Leather Goods: Branding on journals, wallets, belts

Stationery: Business cards, certificates, invitations

Industrial Design: Control panels, tactile indicators

Technical Considerations

| Factor | Details |

|---|---|

| Optimal Substrates | Thick materials (≥300gsm): soft-touch paper, leather, suede, chipboard. |

| Design Tips |

Use bold outlines (fine details may fill when indented).

Avoid narrow borders near edges (risk of tearing).

Pair with foil stamping for "debossed foil" contrast.

Variations |Blind Debossing: No added ink/foil (pure texture).

Color-Deboss: Ink applied inside the indentation.

Combined Effects: Deboss + emboss on opposing sides.

Why Choose Debossing?

Stealth Luxury: Creates refined texture without visual clutter.

Enhanced Usability: Indentations guide user interaction (e.g., braille, button cues).

Brand Memorability: Unique haptic experience elevates perceived value.

Durability: Recessed designs resist abrasion vs. raised elements.

Debossing vs. Embossing

| Debossing | Embossing |

|---|---|

| Recessed design | Raised design |

| Die presses into substrate | Die lifts substrate upward |

| Ideal for soft/thick materials | Works on wider material range |

| Minimalist, subtle effect | Bold, eye-catching presence |

Industry Example: Debossed logos on Apple product packaging convey premium minimalism, while Tiffany & Co. uses embossing for dramatic brand recognition.

Key Terminology:

Brass Dies: Best for deep, crisp debossing

Counter Force: Pressure from the reverse side

Beveled Edges: Slope-controlled indentation walls

Depth Control: Adjustable depression (0.3mm - 2.0mm)

Debossing transforms surfaces into tactile experiences, making it essential for high-end branding and functional design.