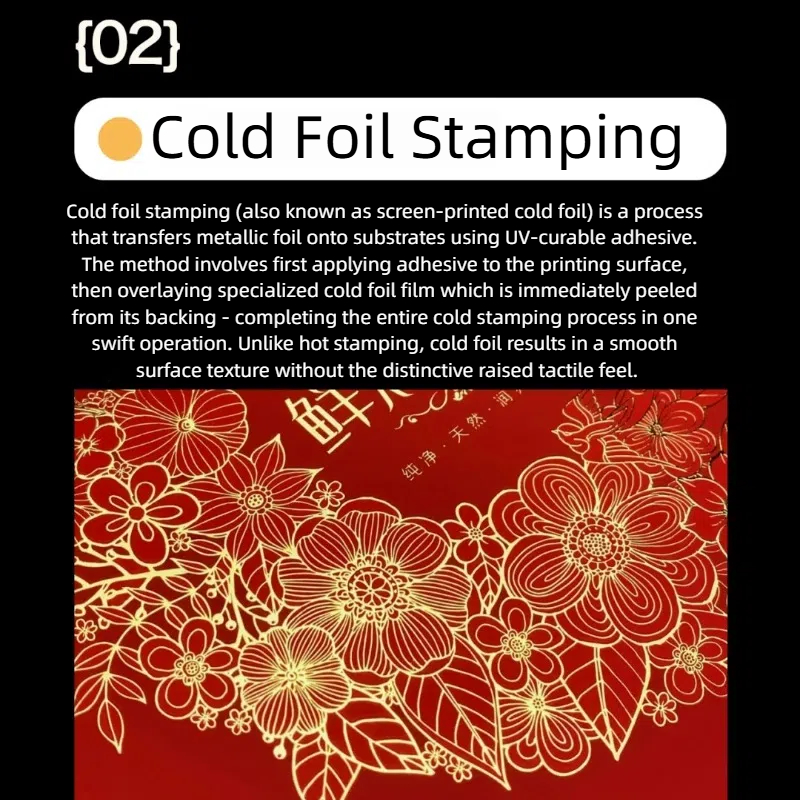

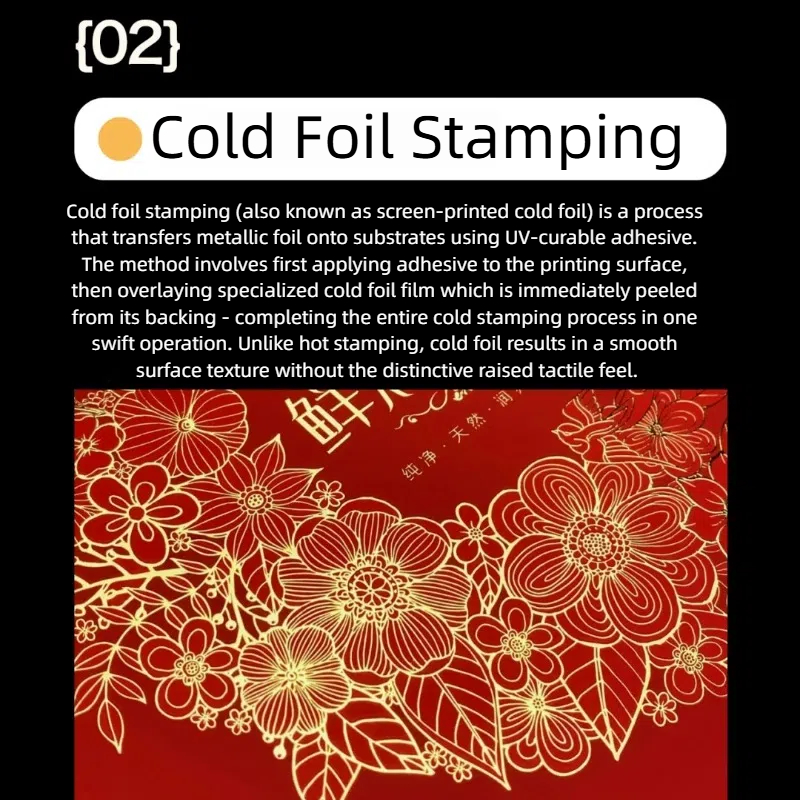

Cold Foil Stamping

Cold foil stamping (also known as screen-printed cold foil) is a process that transfers metallic foil onto substrates using UV-curable adhesive. The method involves first applying adhesive to the printing surface, then overlaying specialized cold foil film which is immediately peeled from its backing - completing the entire cold stamping process in one swift operation. Unlike hot stamping, cold foil results in a smooth surface texture without the distinctive raised tactile feel.

In the printing and packaging industry, "cold foil stamping" refers to a modern foil application process that differs fundamentally from traditional hot foil stamping. Here's the professional technical definition:

Cold Foil Stamping (CFS)

A process where metallic or pigmented foil is transferred to a substrate using UV-curable adhesives at room temperature, typically through flexographic or offset printing units. The foil adheres only to adhesive-coated areas before the excess is removed in-line.

Key Technical Characteristics:

Temperature - Operates at ambient temperatures (unlike hot stamping which requires heated dies)

Adhesive System - Uses UV or EB-curable adhesives applied via printing plate

Process Integration - Can be performed inline with conventional printing presses

Foil Types - Works with specialized cold foil rolls (thinner than hot foil stocks)

Industry Terminology Variations:

Digital Cold Foil (for variable data applications)

Offset Cold Foil (precise registration with offset printing)

Hybrid Cold/Hot Foil (combining both processes)

Technical Advantages:

• Faster production speeds vs. hot foil

• Finer detail reproduction (down to 0.1mm)

• Lower energy consumption

• Compatible with heat-sensitive substrates

Common Applications:

High-volume label production

Folding carton packaging

Security printing features

Promotional printing

This differs from hot foil stamping which relies on heated dies (typically 100-150°C) to transfer foil through heat and pressure. Cold foil is increasingly specified for sustainable packaging as it generates less thermal waste.