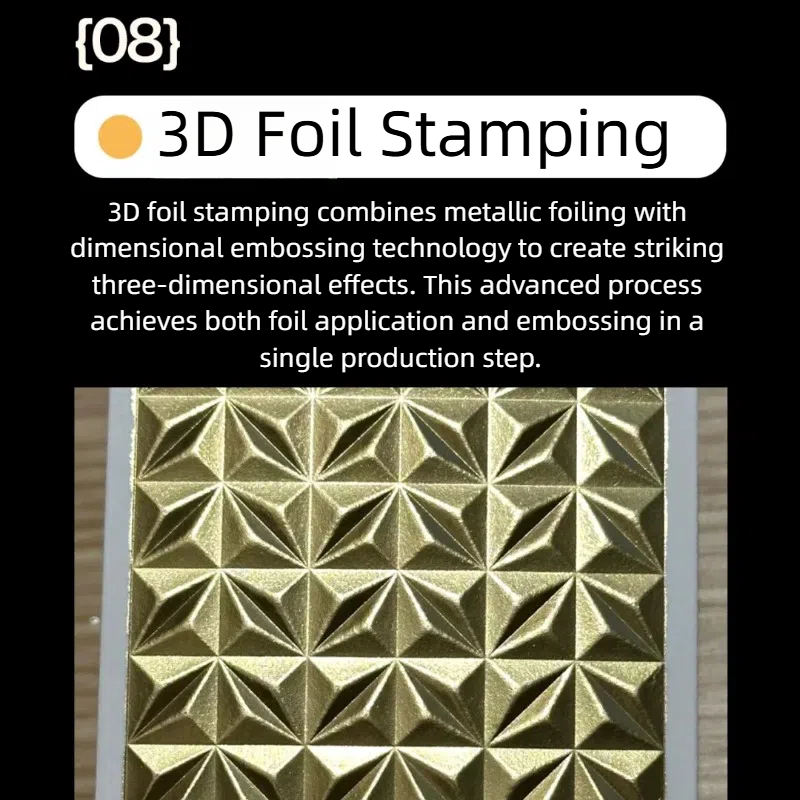

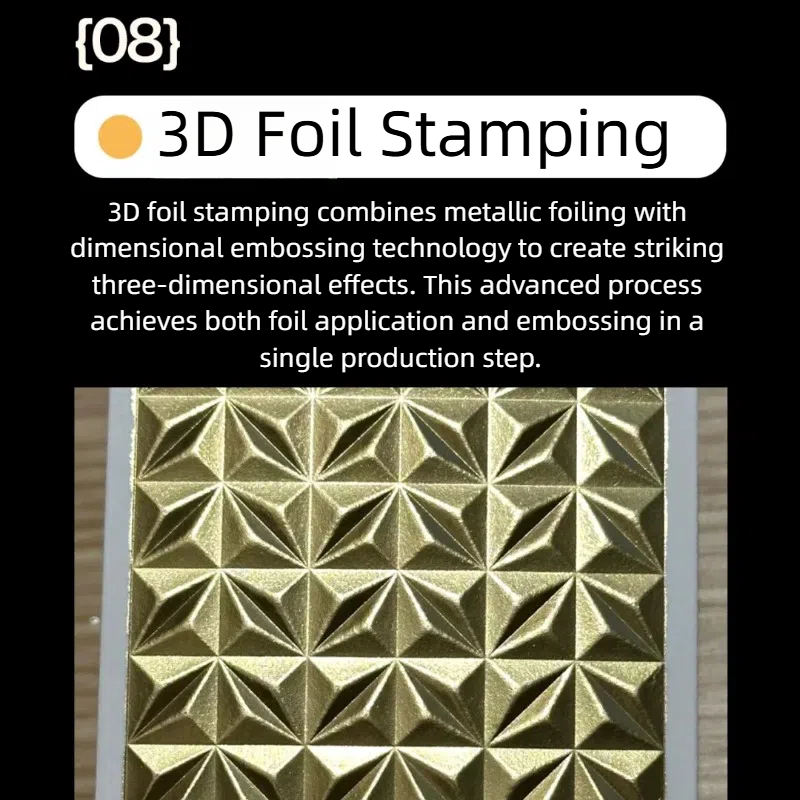

3D Foil Stamping

3D foil stamping combines metallic foiling with dimensional embossing technology to create striking three-dimensional effects. This advanced process achieves both foil application and embossing in a single production step.

3D foil stamping is an advanced hybrid finishing process that combines metallic foil application with high-precision embossing/debossing in a single operation. It creates dramatic tactile and visual effects with dimensional depth, elevating packaging to ultra-premium status.

Key Features

✔ True Depth Effects – Up to 1.5mm relief height for museum-quality textures

✔ Dual Finishing – Simultaneous foil transfer + 3D shaping

✔ Brand Authority – Used by luxury sectors for unboxing experiences

✔ Anti-Counterfeiting – Complex tooling deters replication

Technical Process

Die System

Multi-Level Brass Dies: CNC-machined with:

Foil-transfer surface (upper)

Embossing cavity (lower)

Tolerances: ±0.03mm registration

Foil Options

Metallics (gold/silver/copper)

Pigmented (matte black/white)

Special Effects (holographic, brushed metal)

Stamping Parameters

Temperature: 140–170°C (higher than flat foil)

Pressure: 50–80 kg/cm² (depth-dependent)

Dwell Time: 2–4 seconds

Substrate Requirements

Ideal Materials:

Heavy paperboard (≥350gsm)

Leather/leatherette

Certain plastics (PET/acrylic)

Avoid: Thin/elastic stocks

Applications in Luxury Packaging

| Industry | Use Case | Example |

|---|---|---|

| Spirits | Collector's edition box panels | Louis XIII cognac "The Origin" wooden case |

| Jewelry | Velvet tray liners | Cartier ring box medallions |

| Automotive | Branded gift sets | Rolls-Royce key presentation boxes |

| Electronics | Premium device sleeves | Bang & Olufsen headphone cases |

Comparison: 3D vs. Standard Foil Stamping

| Factor | 3D Foil Stamping | Standard Foil Stamping |

|---|---|---|

| Dimensionality | Tactile depth (0.3–1.5mm) | Flat surface only |

| Production Speed | 30–50% slower | Faster |

| Tooling Cost | 3–8× higher | Lower |

| Effect | Sculptural luxury | Decorative enhancement |